EPS Sandwich Panel Machine

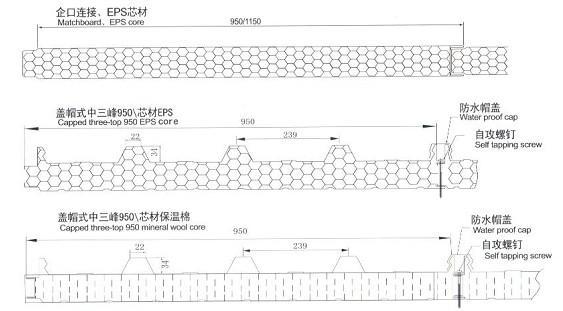

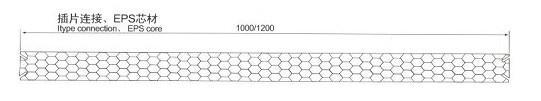

The production line can produce color steel sandwich panel with various specifications including EPS flat board, EPS match

board, EPS corrugated sheet board, Mineral wool flat board, Mineral wool match board, Mineral wool corrugated sheet board

etc.

Main parameter

a. Uncoiler

|

|

Manual |

|

Material of coil: |

color coating coil |

|

Thickness of sheet: |

0.3~0.8mm |

|

Width of coil: |

1250mm |

|

Weight of coil: |

≤ 5 t |

|

Inside diameter of coil: |

480~520mm |

b. Into Shearing Device

|

Type of Shearing: |

Electrical Shearing |

|

Driven Power: |

0.75 kwc. |

c. Forming Machine Itself

|

Design of profile: |

see list and drawings attached |

|

Type of forming: |

single layer forming |

|

Stands of forming: |

16 stands |

|

Roller diameter: |

¢80mm |

|

Material of roller: |

45 steel heat treatment |

|

Thickness of chromic plating of roller surface: |

0.05~0.06mm |

|

Speed of forming: |

5~6.0m/min synchronies with panel machine |

|

Type of synchronies: |

electrical synchronies |

|

Driven power: |

3.0 kw |

|

Installation instruction: |

two parts |

|

Size of forming machine: |

11000×2200×2200mm |

|

Weight of forming machine: |

~6 t |

d. Control Panel

|

Electrical Voltage: |

380V/3Ph/50Hz |

|

Type of controlling: |

PLC (Mitsubishi Japan) |

|

Touch screen: |

Mt506 (Taiwan) |

|

Speed measure device: |

OMRoM (Japan) |

|

Parts of electrical control system: |

Simenz |

|

Transducer: |

(Mitsubishi Japan)/0.4KW (Made in China) |

|

Model: |

SPC Machine |

Drawing

Specification

|

Product |

Measuremm |

Weight (kg) |

Total Power(kw) |

Production Efficienc(n/min) |

|

SANWICH PANNEC PEODUCE LINE |

24000×2100×2600 |

15700 |

25 |

1-4.2 |

|

SANWICH PANNEC PEODUCE LINE |

25000×2000×2400 |

18000 |

20 |

1-4 |

|

SANWICH PANNEC PEODUCE LINE |

23000×1980×2000 |

16400 |

22 |

2-5 |

|

SANWICH PANNEC PEODUCE LINE |

26300×2000×2600 |

15600 |

25 |

1-4.2 |

|

SANWICH PANNEC PEODUCE LINE |

240000×2000×2100 |

17500 |

25 |

2-5

|

https://youtu.be/cY6D45hYBI0

- 上一篇:没有了

- 下一篇:rockwool sandwich panel production line