3D Panel Machine

Summary

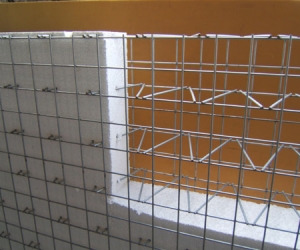

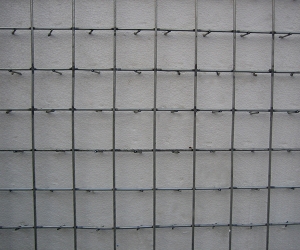

The 3D panel products are widely used in constructions, to be the heat insulation. The upper steel mesh, EPS block and bottom steel mesh are welded through skew steel wire by 3D penal machine. All process are controlled by computer, the welding angle is adjustable.

The complete equipment is controlled by PLC, made up of fixed steel wire frame and EPS board, manually load the board, wire frame loaded integrately and automatic unload the finished product. The oblique wire is guided by steel tube, automatic cut with position limit switch controlling the cutting lenth. The Hydraulic Power Transmission System is used for easier working position adjustment and the quto feedback system is also adopted in the electrical control system for fualt alarm and faster solution.

|

|

|

|

Specification

Model: XCS-4B

Product size: (2000-6000)*1200*(40-100)mm

Capacity: 40-60m2/hr

Wilding strenght: pull-off force for each spot ≥680N

3D panel lateral buckling strength: ≤L/660mm

3D panel diagonal tolerance: ≤5mm

3D panel omissive welding: ≤3%

Wire diameter: 3.0-4.0mm

Power: 380V/50Hz 75Kw

Weight: 8000kg

Contour size: 16000x1850x2600 mm

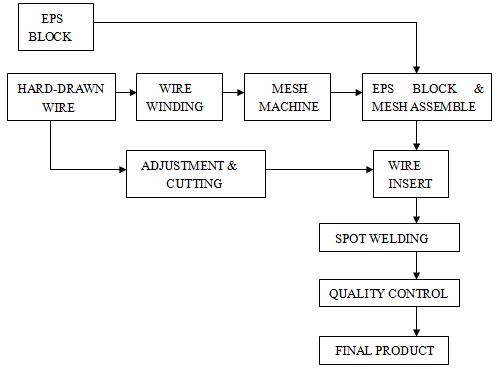

3D PANEL PROCESS

Main Parameters:

|

Board Dimension and accepted tolerance |

|||

|

Length |

2.4~3m |

Thickness |

70~200mm |

|

Width |

1.22m |

Diagonal Length Error |

≤10mm |

|

Overall Dimension |

|

|

Length*Width*High |

16m*6m*1.8m |

|

Weight |

About 4500KG |

|

Welding Index |

|

|

Welding Strength |

≥450N |

|

Welding Shortage |

≤5% |

|

Power Information |

|

|

Connecting Power |

≤60KWA |

|

Voitage |

380V |

|

Rate |

50HZ |

|

Material Performance Index |

|

Steel Wire Diameter:2~3mmm, Low Carbon, Zn-Plated, Cold Drawing Wire; Tensile Strength:70~850N/mm2 |

|

EPS Volume Weight≥16KG/m3, Flame retardant, Oxygen Index≥30 |

Applications:

https://youtu.be/EI9X_8j9Cy4

- 上一篇:没有了

- 下一篇:没有了