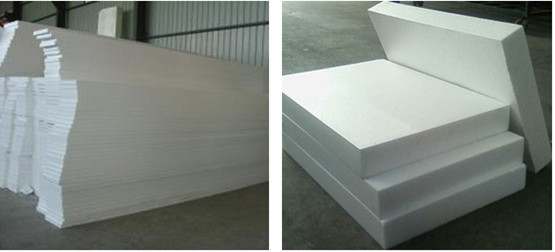

EPS Cutting Line

Summary

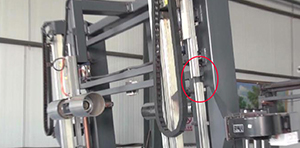

1. Increase the grade A unique hanging wire rack;Optional automatic adjustable wire (according to the formula of the modified flame retardant), increase the wire speed.

2. The horizontal, vertical, cut off respectively using vibration cutting, can complete modification of benzene boards with flame retardant after cutting, reduce incision at the same time, increase the smoothness.U-shaped arrangement of cutting line for domestic at present all modified benzene board of flame retardants formula;Type I decorate the cutting line suitable for flame retardant modified benzene board in alcoholic solvents.

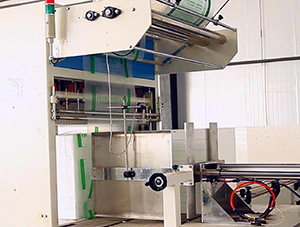

3. Continuous conveyor drive roller and the rod according to the modified high density characteristics of benzene board, adopt high design, increasing the use of stability and the service life of equipment.

4. Continuous cutting, greatly increase the cutting efficiency.

5. Automatic positioning device, which can guarantee the cutting precision.

6. Optional automatic packaging system, increase the packing speed, reduce labor costs.

7. Automatic storage plate conveyor system and automatic flip upper body be automatic production (this system is optional).

Specification

| No. | Items | Unit | CM/L(2000-6000) |

| 1 | Block net length | mm | 2000-6000 |

| 2 | Block net width | mm | 1200 |

| 3 | Block net thickness | mm | 600/1000/1200 |

| 4 | Max. wire setting | pcs | 31+ 3 + 15 |

| 5 | Cutting speed(20g/l) | m/min | 1.5-2 |

| 6 | Compressed air pressure | bar | 6-8 |

| 7 | Power | Kw | 32 |

Features

|

|

| A. Automatic wire setting system, finished with 2 minutes. | B. Horizontal Vibration Cutting, 50% cutting speed higher. |

|

|

| C. Vibration wire & spare ware speration design. | D. Vertical vibration cutting, increase 50% cutting speed. |

|

|

| E. Automatic positioner insure cutting precision. | G. Scrape crusher system. |

|

|

| F. Film packing system. | H. Two side labeller. |