Advantages of the external walls with EPS Cornice

Update: 2015-11-19 09:27 View:

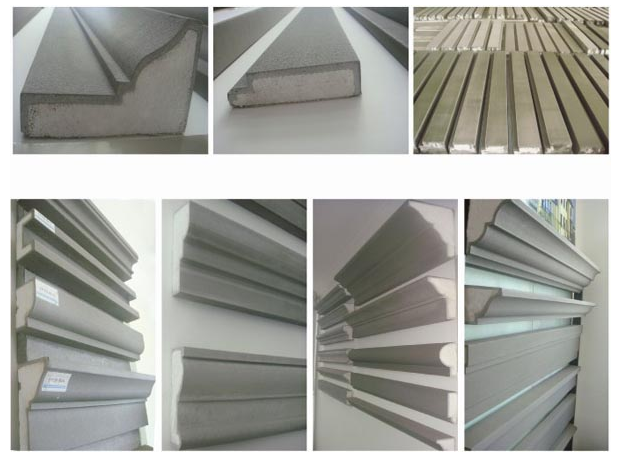

EPS cornice is a new application of wall decoration and components, which can completely replace

the traditional cement (GRC) member, more suitable for installation in facades EPS, XPS insulation

on the walls, which reflects the European classical, tastefully decorated style, but also ensures that

the external walls of the main building does not appear cold, thermal bridges. Especially for

European-style high-rise buildings, installation of cement components is very difficult, long duration,

over time there will be cracks, poor durability, while the use of EPS cornices, with easy installation,

economy, long durability and other advantages. EPS is polystyrene cornice B2 level by the release

of the main fire, paste alkali-resistant fiberglass mesh, to special adhesive outer protective layer

composite. Not affected by temperature changes, cold, heat; free from damp climate and the impact

of acid rain.EPS cornice of fire and can not emit toxic substances, environmental protection high

quality decorative building materials. EPS cornices using computer numerical control cutting, making

quick, multi-species models, such as cornices, Roman, window cover, brackets, etc., can be installed

on the four sides of the window, door, eaves and walls; so the building facade more beautiful, more

architects who brought a new, different kind of creativity.

1, light weight . In 50 × 50cm of EPS cornices, for example, its weight is about 1/6 of GRC decorative

cornices. A person can freely move and construction.

2, a solid paste. EPS cornice security is very important, especially the quality system requirements for

life, if only heavy landscaping, do not pay attention to the security risks that would be great. EPS

decorative cornices not only lightweight, but also very strong bond with the base surfaces. It is mainly

used polymer adhesive mortar, mortar and polymer is added to an organic glue made of inorganic

material cement mortar mixing, not only long life, and a strong bond, and have national standards and

norms, and in a large number of engineering application proves feasible, it is safe and reliable.

Replacing quality accident due to the use of fixed anchor bolt corrosion green construction risks and

hazards caused.

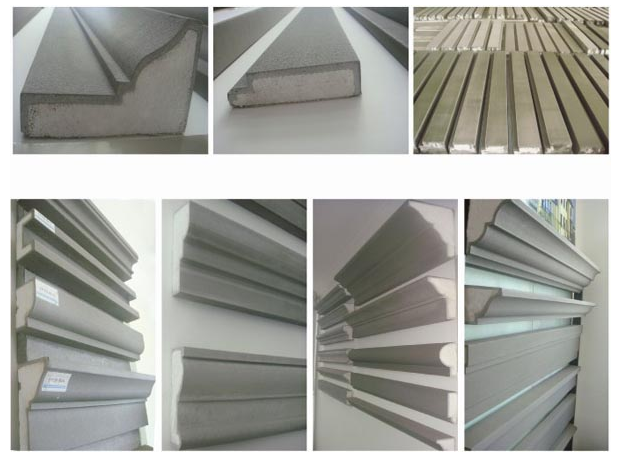

3, random process modeling. Because it is a computer design style automatic cutting cornices (pieces)

style arbitrary, processing is simple, easy to install.

4, and EPS external wall insulation with the use of better, the rapid development of building energy

efficiency today, EPS board exterior insulation system is the only system of choice, but they worry

about whether the architect will affect the achievement of facades, EPS decorative cornices completely

dispel concerns architects, not only that, but the architect can design arbitrary shape, form a perfect

fit with the outer wall insulation,

5, EPS cornices and easy to install. Use of special adhesive materials and methods, one person can

install and construction, especially in the larger volume member, simply bonded installation.

6, EPS cornice (pieces) smooth, beautiful, no gap between linear. The use of patching material gap

between the two lines, is the gap all but disappeared. In the future use will not crack.

7, EPS cornice (member) of the biggest advantages is that she completely solved the cold exterior

insulation, thermal bridge problems.

the traditional cement (GRC) member, more suitable for installation in facades EPS, XPS insulation

on the walls, which reflects the European classical, tastefully decorated style, but also ensures that

the external walls of the main building does not appear cold, thermal bridges. Especially for

European-style high-rise buildings, installation of cement components is very difficult, long duration,

over time there will be cracks, poor durability, while the use of EPS cornices, with easy installation,

economy, long durability and other advantages. EPS is polystyrene cornice B2 level by the release

of the main fire, paste alkali-resistant fiberglass mesh, to special adhesive outer protective layer

composite. Not affected by temperature changes, cold, heat; free from damp climate and the impact

of acid rain.EPS cornice of fire and can not emit toxic substances, environmental protection high

quality decorative building materials. EPS cornices using computer numerical control cutting, making

quick, multi-species models, such as cornices, Roman, window cover, brackets, etc., can be installed

on the four sides of the window, door, eaves and walls; so the building facade more beautiful, more

architects who brought a new, different kind of creativity.

1, light weight . In 50 × 50cm of EPS cornices, for example, its weight is about 1/6 of GRC decorative

cornices. A person can freely move and construction.

2, a solid paste. EPS cornice security is very important, especially the quality system requirements for

life, if only heavy landscaping, do not pay attention to the security risks that would be great. EPS

decorative cornices not only lightweight, but also very strong bond with the base surfaces. It is mainly

used polymer adhesive mortar, mortar and polymer is added to an organic glue made of inorganic

material cement mortar mixing, not only long life, and a strong bond, and have national standards and

norms, and in a large number of engineering application proves feasible, it is safe and reliable.

Replacing quality accident due to the use of fixed anchor bolt corrosion green construction risks and

hazards caused.

3, random process modeling. Because it is a computer design style automatic cutting cornices (pieces)

style arbitrary, processing is simple, easy to install.

4, and EPS external wall insulation with the use of better, the rapid development of building energy

efficiency today, EPS board exterior insulation system is the only system of choice, but they worry

about whether the architect will affect the achievement of facades, EPS decorative cornices completely

dispel concerns architects, not only that, but the architect can design arbitrary shape, form a perfect

fit with the outer wall insulation,

5, EPS cornices and easy to install. Use of special adhesive materials and methods, one person can

install and construction, especially in the larger volume member, simply bonded installation.

6, EPS cornice (pieces) smooth, beautiful, no gap between linear. The use of patching material gap

between the two lines, is the gap all but disappeared. In the future use will not crack.

7, EPS cornice (member) of the biggest advantages is that she completely solved the cold exterior

insulation, thermal bridge problems.